- +91 81208 40242

- alexandritepowersystem@gmail.com

- 245 Satya Dev Nagar, Indore- 452009

Close

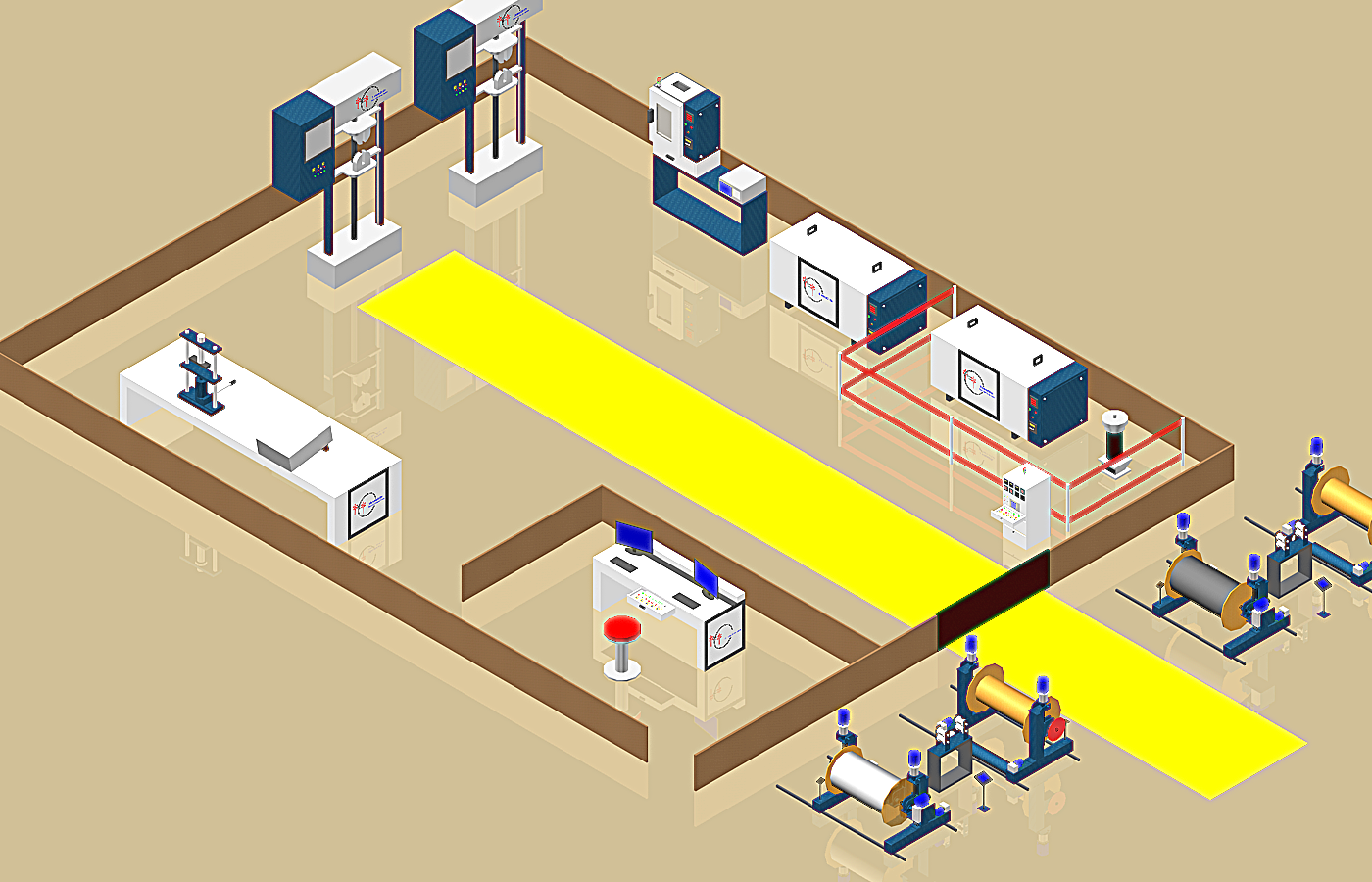

In APC System, we offer a wide range of customized products for Acceptance Testing Laboratories for Electrical Distribution System Material Testing including the Design, Development and Commissioning.

Urban development projects, including the construction of commercial and residential complexes, contributes to the need for enhanced power distribution infrastructure, thus driving the demand for good quality HL/LT cables, overhead line conductors, insulators, switchgears etc… So, the industries are manufacturing the Electrical Distribution System Material on a mass scale and conducting Acceptance tests, which are necessary to be performed on all electrical material to ensure the quality of the product.

APCS Acceptance Test system specifically designed to test Electrical Distribution System Material as per international standard. Through good electrical equipment’s, instruments and auto report generation software APCS test system will increase the productivity and reduce the testing time & human errors at the same time.

| Sr.No. | Electric Material | Tests |

|---|---|---|

| 1 | Overhead AAAC Covered XLPE Conductor | • Ultimate Tensile Strength Test. • Electrical Resistance Test. • Wrapping Test. • Bending Test. • Water absorption Test. • Hot Set Test on XLPE. • Ultimate Tensile Strength Test on XLPE. • Elongation at break on XLPE. • Pressure Test. • Shrinkage test on XLPE. • Volumetric Resistivity Test. • Insulation Resistance Test. • Spark Test. • Power Frequency Test. |

| 2 | Overhead LV ABC XLPE Conductor | • Ultimate Tensile Strength Test(Individual wire greater than 16mm2). • Electrical Resistance Test. • Wrapping Test. • Bending Test. • Water Absorption Test. • Hot Set Test on XLPE. • Ultimate Tensile Strength Test on XLPE. • Elongation at break on XLPE. • Shrinkage test on XLPE. • Insulation Resistance (Volumetric Resistivity at Room Temperature). • Insulation Resistance(Volumetric Resistivity at 90 Degree Celsius). • Spark Test. • Power Frequency Test. |

| 3 | Single Core Stranded Compacted Circular Copper Conductor XLPE Insulated Screened Aluminum Wire Armoured PVC Sheathed Cable | • Tensile Strength of XLPE Insulation. • Elongation of XLPE Insulation. • Tensile Strength of Outer Sheath. • Elongation of Outer Sheath. • Hot Set Test at 200±3 degree C for XLPE Insulation(Elongation Under Load and Permanent Elongation after Cooling. • Conductor Resistance at 20 degree Celsius. • High Voltage Test 21kV for 5 Minutes. • High Voltage Test 4Uo for 4 Hours. • Volumetric Resistivity(Insulation Resistance) at room temperature. • Volumetric Resistivity(Insulation Resistance)at 90 degree Celsius. |

| 4 | Electrical Bare Conductor | • Ultimate Tensile Strength Test. • Electrical Resistance Test. • Wrapping Test. • Torsion Test. • Elongation Test. • Galvanizing Test. |

| 5 | Insulators | • Temperature cycle test. • Twenty four hours mechanical strength test (for string insulator). • Electro-mechanical failing load test (for string insulators). • Mechanical failing load test. • Puncture test. • Porosity test and. • Galvanizing test. • Mechanical routine test. • Electrical routine test. |

| 6 | Breaker | • Function Test. • Insulation Test on Main Circuit. • Insulation Test on Auxiliary Circuit. • Power Frequency Test on Auxiliary Circuit. • Power Frequency Test on Main Circuit. • Contact Resistance Test. • Capacitance and Tan Delta Test. • Automatic Circuit Recloser Test. • Breaker Timer Measurement Test. |

| 7 | FUSE LINK | • Power Frequency Test. • Temperature Rise Test. • Time-Current (TC) characteristics curves Tests. • Preloading adjustment factors or curves. • Ambient temperature adjustment factors or curves. |

| 8 | Disconnecting Switch | • Power Frequency Test. • Temperature Rise Test. |